Produced for highest demands

Accurateness, quality assurance und know-how - that is how we achieve high class tungsten carbide

Manufacturing of our tungsten carbide -MADE IN GERMANY- is continuously screened by the quality management. The experience of several decades, analyses, improvements and innovations made our product to the current high performance carbide it is today.

It is a very complex case to produce carbide and all parameters have to fit exactly so that our customers always receive the quality they were used to.

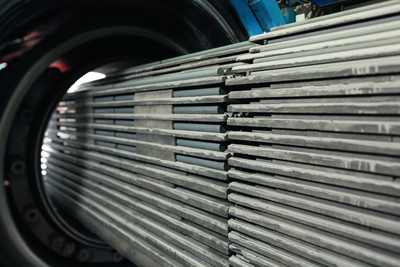

At the beginning WC, Co and doping elements are mixed according to our special recipes. This mixture is then ball-milled for several hours and afterwards sieved for an outstanding homoge-nous distribution of carbide grains of the specific grade powder. With the help of organic additives, the powder is plasticized in our kneaders into a clay like dough that can be extruded. Through our patented production technology the plasticized mixture is then extruded. There-by coolant ducts with different helical angles and geometries can be realized in our round rods.

Subsequently, part of the added liquids must be slowly removed from the product under strictly controlled conditions in our climate chamber and special drying-furnaces. The drying time depends on the outer diameter. Main and counter spindle, two turrets, six linear and two round axes as well as a specially adapted bar loading and part removal system – with these prerequisites, preforms can be produced fast, economical and reliable to meet customer requirements. At the beginning, the residual plasticizers evap-orate during the dewaxing process. After further heating, the Co melts at about 1380 °C and flows into the free spaces between the WC grains. Through the hot-isostatic process, the remaining porosity is removed and the product subsequent-ly cooled. The cemented carbide products lose up to 25% in volume during the whole Sinter-HIP process.

All of our carbide rods were produced in Germany and each one can be tracked rigth to its start.

Do you have further questions?

Please write a mail or call our team!